- HOME

- Sustainability

- Monozukuri and the Value Chain

- Research, Development, and Verification

Research, Development, and Verification

Monozukuri and the Value Chain

Development and technology research sites and the Central Testing Center Laboratory

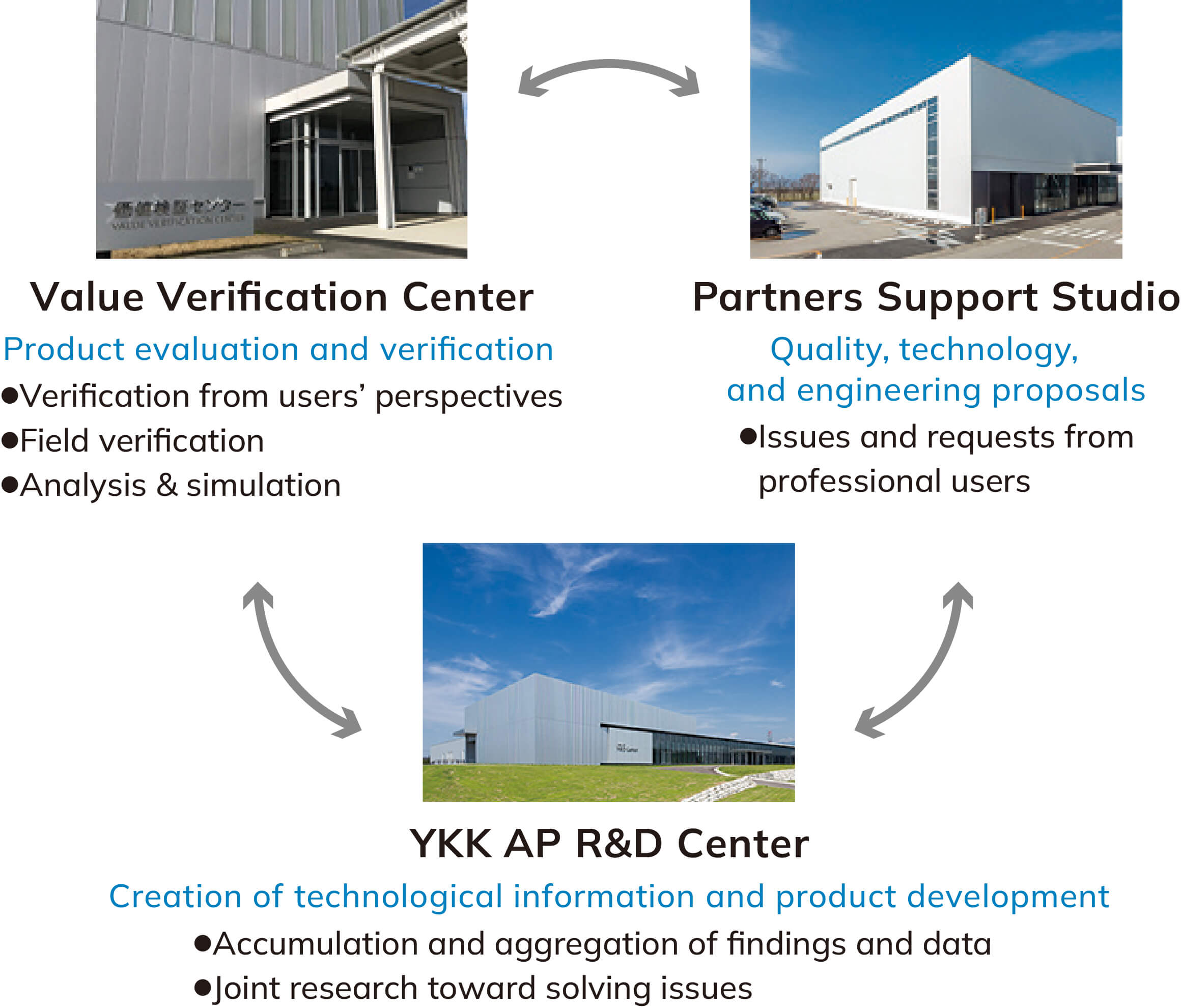

The YKK AP R&D Center, Value Verification Center, and Partners Support Studio, all located in Kurobe City, Toyama Prefecture, are responsible for the cycle of development, evaluation and verification, technical proposals, and information communication that form the foundation of YKK AP's monozukuri process. The YKK AP R&D Center is a center of technology and expertise which develops high-quality products. The Value Verification Center conducts "user verification" using consumer monitors and "field verification" that reproduces the natural environment. Finally, the Partners Support Studio presents proposals aimed at addressing the issues of professional users, based on our technology. Furthermore, the Central Testing Center Laboratory, a JNLA testing laboratory that meets international standards, reinforces our product quality assurance system through rigorous testing.

Development and technology research sites

Global R&D organization

YKK AP has also strengthened its global research and development system. In addition to Japan, R&D centers have been established in Germany and Indonesia to conduct research and studies in different regions: Japan for warmer regions, Germany for colder regions, and Indonesia for hot and humid regions. This information is compiled and shared to develop products optimally suited to each region.

At the YKK AP R&D Center (Germany), we investigate and research innovative European technology in the fields of energy conservation architecture and building materials, and promote high added-value in windows and doors through functional parts, thermal insulation of windows and doors, and frames and glass, etc.

At the YKK AP R&D Center (Indonesia), we conduct investigations, research, and development related to energy conserving construction methods and windows and doors suited to hot and humid regions, as well as research on passive design (the design of comfortable living environments that utilize natural energy). As part of a joint industry-government-academia research project on "energy-conserving multi-family residences for middle-income residents," we are measuring the effectiveness of using windows and entrance doors that provide effective ventilation.

Global R&D organization

Technical Research Division Initiatives

The Technical Research Division is responsible for technology, research, and development from a global perspective. It is working on technology, research, and development for new technologies and new materials, including the development of recycling technology to achieve a 100% aluminum recycling rate and the development of organic materials to become carbon neutral. It is also striving to advance our technologies in existing areas, such as building technologies for ultra-high thermal insulation glass. Moreover, through joint research with external research institutions, efforts are underway to promote the development and exchange of human resources.

Product safety and quality assurance

Product safety and quality assurance are essential in Monozukuri. YKK AP has strived to ensure the safety of its products under the "YKK AP Product Safety Basic Policy", aiming to contribute to the establishment of a "product safety culture" promoted by the Ministry of Economy, Trade, and Industry and to deliver safety and peace of mind to customers. In the category of large manufacturers and importers in the "Award of Excellency for Product Safety Measures (PS Award)", YKK AP received the Minister of Economy, Trade and Industry Award, the most prestigious award, in 2010, 2014, and 2017 and has retained the certification of "Product Safety Measures Gold Company" since November 2017. In 2022, YKK AP's ongoing commitment and development in safety measures were acknowledged through a follow-up assessment conducted every 5 years, leading to the continuation of its certification.

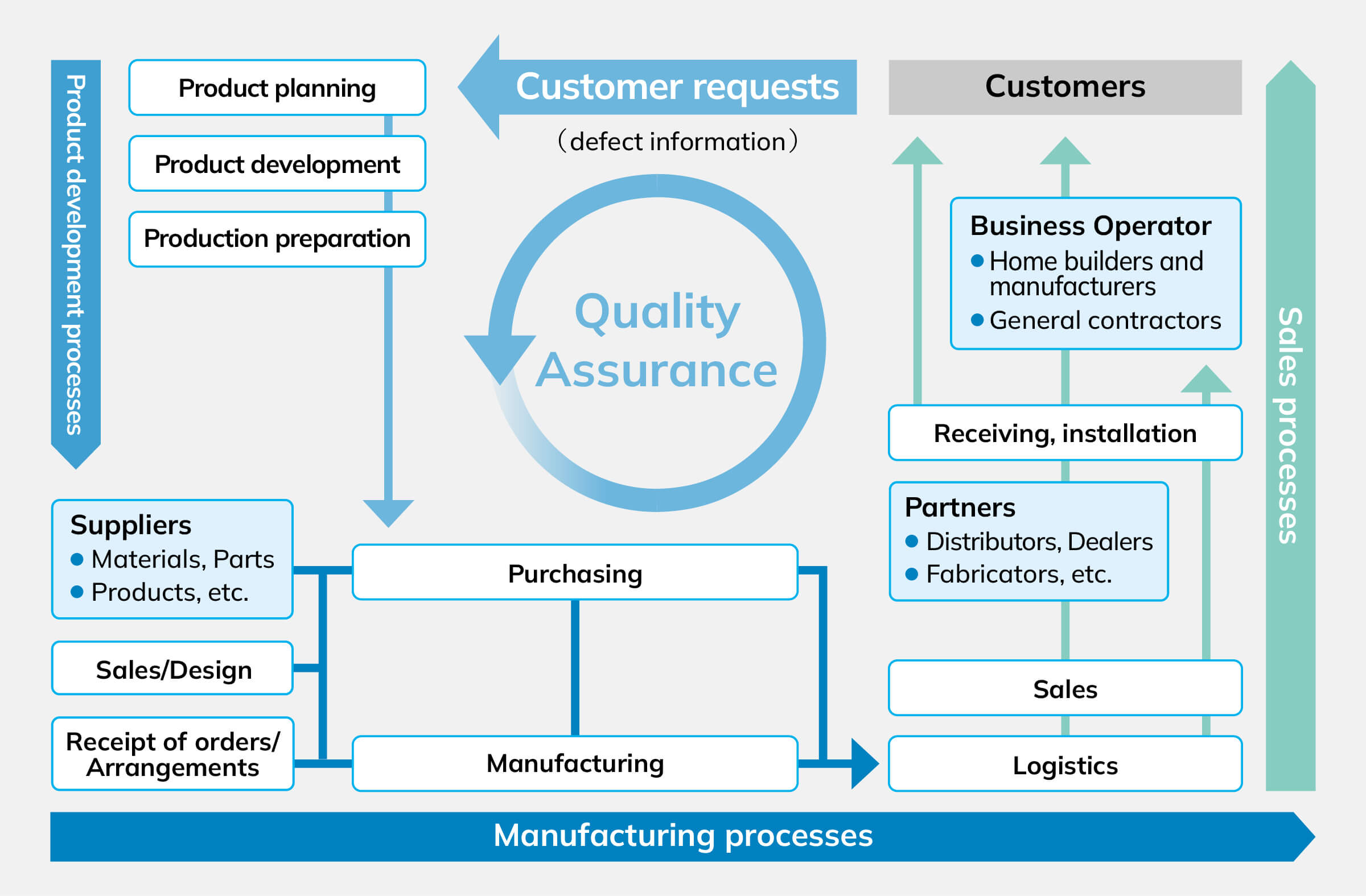

In 2019, YKK AP established the "Quality Assurance Division" to promote the operation of quality assurance processes throughout the supply chain, from product development to production and sales, ensuring product quality. We are also actively working to centralize customer and partner feedbacks, defect reports, and feedbacks on inspections and repairs as information on quality. This initiative aims to achieve early resolution and prevention of defects, contributing to high customer satisfaction and providing societal values through our high-quality products.

(Ministry of Economy, Trade and Industry)

November 2017

- Certification extended in January 2023